Functional description and benefits

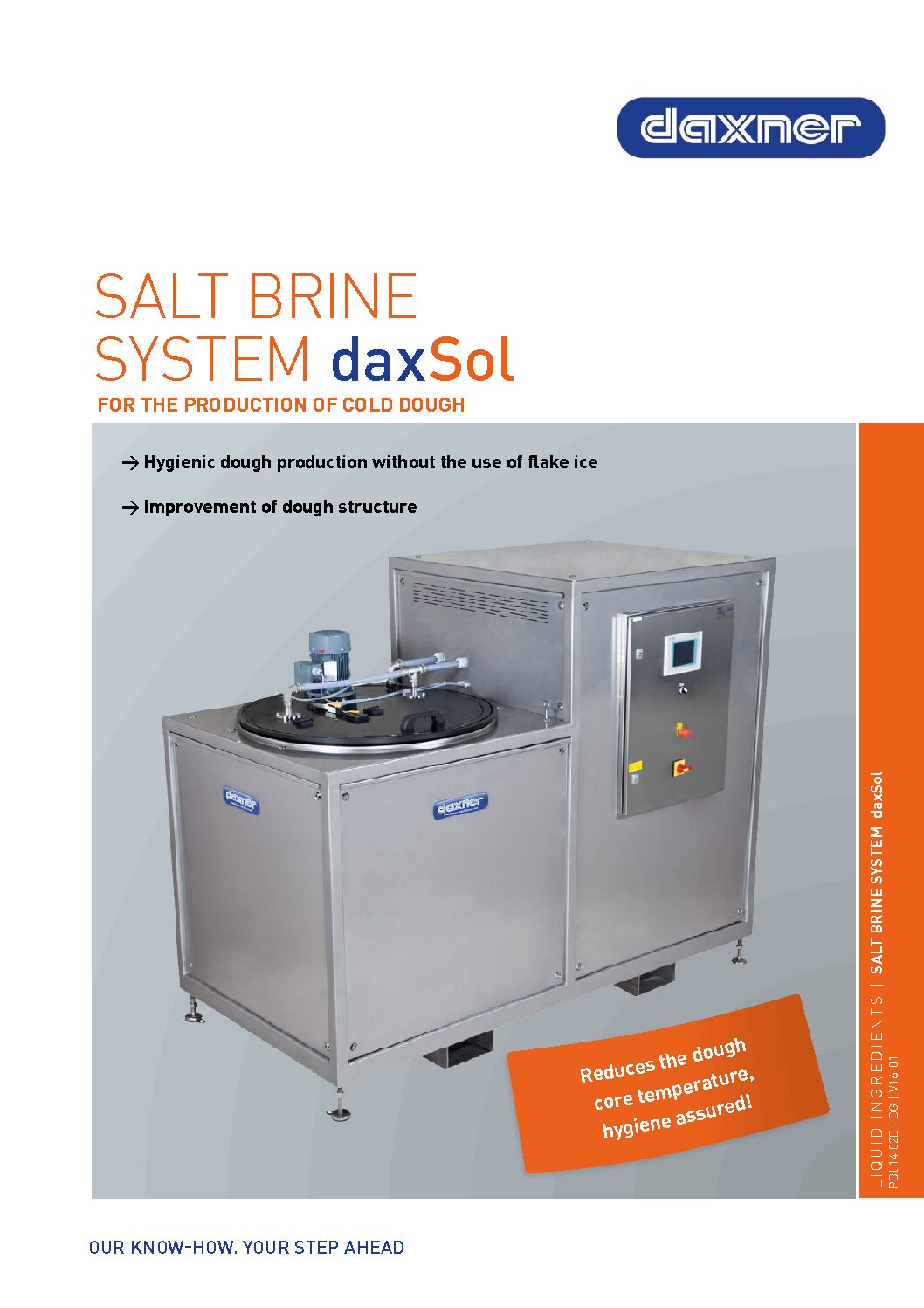

The salt brine system is used for the production of cold dough.

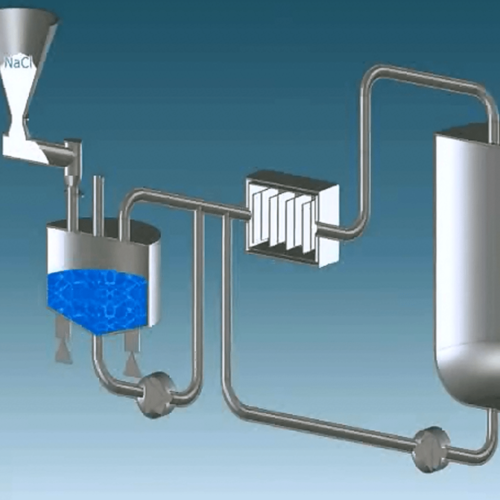

Into a preparation vessel, filled with water (defined quantity), the salt will be dosed according to the desired concentration. The resulting solution is passed through a heat exchanger to cool down to the preset temperature. The cooled brine is stored in a storage tank and will be fed to the consumers as required. Intermediate circulations support the stability of the solution and its temperature.

Salt brine:

In addition to the crystalline dosage of salt can be dissolved in water, whereby the quantity of salt in water will be determined by the maximum saturation level (temperature-dependent). Under ideal conditions approx. 310g salt can be dissolved in 1000g water. Such a solution has different physical properties to water. Thus, among other things, the freezing point will be lowered, which depending on the concentration of the brine, will be much lower than 0°C.

This means that a 15% salt brine solution (under laboratory conditions) will only freeze at approx. -9°C. Of course, this “cold” solution is an ideal medium for controlling the dough temperature. The dough temperature can be kept within narrow limits, so the addition of flake ice is not necessary.

Due to the aggregate state of the solution, the structure of the dough will not be impaired, since there are no sharp edged ice crystals. Due to the automatic addition of the salt brine, without manual manipulation, the hygienic aspects in the dough preparation will be enhanced.

Advantages

Sterile

Simple, accurate dosing

No temperature fluctuations

No ice flakes needed

Dough structure is improved

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Sounds interesting?

Let us know.

Send us your inquiry and a technical sales person is calling you back to talk about your projects or find a DAXNER partner company around you.